Stainless steel plays an increasingly important role in many production sectors such as food, pharmaceutical, livestock, medical, culinary, interior and exterior furnishings, naval and also in medium high construction engineering.

The fundamental role played by this material, in all these sectors (so different from each other) is due to its excellent anticorrosive and antioxidant properties. It also has a relative resistance to acids, chlorides and bases, an infinite recyclability and an almost eternal duration. Among the main characteristics of stainless steel, which make it one of the fundamental elements in the food, canning and zootechnical industry, we find the ability to avoid bacterial proliferation without altering the flavors of the food that is cooked or stored in contact with this material.

Properties and classification of stainless Steel

Corrosion resistance, typical of stainless steel, is obtained by adding 10.5% chromium to the alloy. Chromium forms a protective surface film that has no reaction in contact with oxygen, thus preventing surface oxidation, commonly called rust, as it happens with carbon steel. However, it should be noted that stainless steel loses this characteristic if used in highly saline and acidic environments without prior surface protection, through operations such as pickling or electropolishing.

How are stainless steels classified? How can we choose the stainless steel suitable for our use? There are in fact different types of stainless steel, distinguished according to the components of the alloy and the different end-uses of the material.

Stainless steels are divided into three big families:

• The Martensitics

• The Ferritics

• The Austenitics

Types of Stainless Steel

Martensitic Stainless Steel

Martensitic stainless steel has an alloy with chromium from 11% to 18% and contains small amounts of other elements, such as nickel. Martensitic steels are the only ones that can be hardened to increase their mechanical characteristics such as hardness, tensile strength and yield strength. They are excellent in case of hot deformation processes, they have excellent electrical conductivity, but a modest resistance to corrosion, low welding aptitude, high surface hardness and good resistance to fatigue stress. They are used in bolts, screws, gear construction, industrial cutlery and in machinery where resistance to stress is required. They are classified with the acronym 4XX.

Ferritic Stainless Steel

Ferritic stainless steel has a chromium alloy in a percentage from 16% to 28%. Ferritic steels don’t raise their mechanical characteristics through heat treatments, therefore it is preferable to carry out the annealing treatment to work them at their best. They have excellent mechanical workability, an excellent degree of cold deformation, good resistance to corrosion and wear, but only under tension. They’re used in the production of low-quality sinks, crockery and cutlery, in construction and in the energy and automotive sectors, also due to its low cost. Ferritic stainless steels too are classified with the code 4XX.

Austenittic Stainless Steel

Austenitic stainless steel is a nickel-chromium alloy in a percentage from 16% to 27%, nickel from 7% to 22% and molybdenum from 3% to 6%. Austenitic steels are used mostly in the pharmaceutical, chemical, medical, zootechnical, but above all in food sectors. They are non-magnetic, optimally cold workable and excellent for welding. Their basic properties include easy cleaning and sanitizing and their hygienic coefficient. The best known are classified with the acronym 3XX.

Condor’s Experience

For the production of stainless steel products, our company has been using, for over 58 years, only certified first quality austenitic steels AISI 304, 304L, 316, 316L and only of European origin.

Over the years we have accumulated many and valuable experiences, which have allowed us to become a world leader in the production of stainless steel components for milking parlors, stainless steel tanks for containing and transporting milk and food liquids and all their accompanying accessories and completion, always strictly of stainless steel. The production experience gained has allowed Condor to expand its offer by creating customized items, even in small and single quantities, and to present itself as a flexible and reliable partner, providing the customer with the finished and certified product.

Condor’s Stainless Steel Treatments

Over 20 years ago we expanded our offer, starting to operate in the sector of surface treatments of stainless steel, performing brilliant electropolishing, pickling, passivation, round and flat satin finishing, micro shot peening, deburring and tumbling. Electropolishing makes austenitic stainless steel further resistant to corrosion and oxidation. This treatment, carried out by us directly within our company, makes the products perfectly suitable for contact with food and this allows us to distinguish our products with the FOOD - MOCA brand.

The achievement of two important certificates is a recognition of the company's continuous improvement objectives: the UNI EN ISO 9001: 2008 certification and the food suitability of the items produced with the possibility of distinguishing them with the important "Food Contact Materials or MOCHA". Our first constant commitment is to improve every day, continuously, in the management of the total quality of our work, with particular attention to customer satisfaction.

Custom Made

Custom-made productions are our main strength. We are specialized in “Custom-Made” production based on the individual needs of each customer, even for single pieces only.

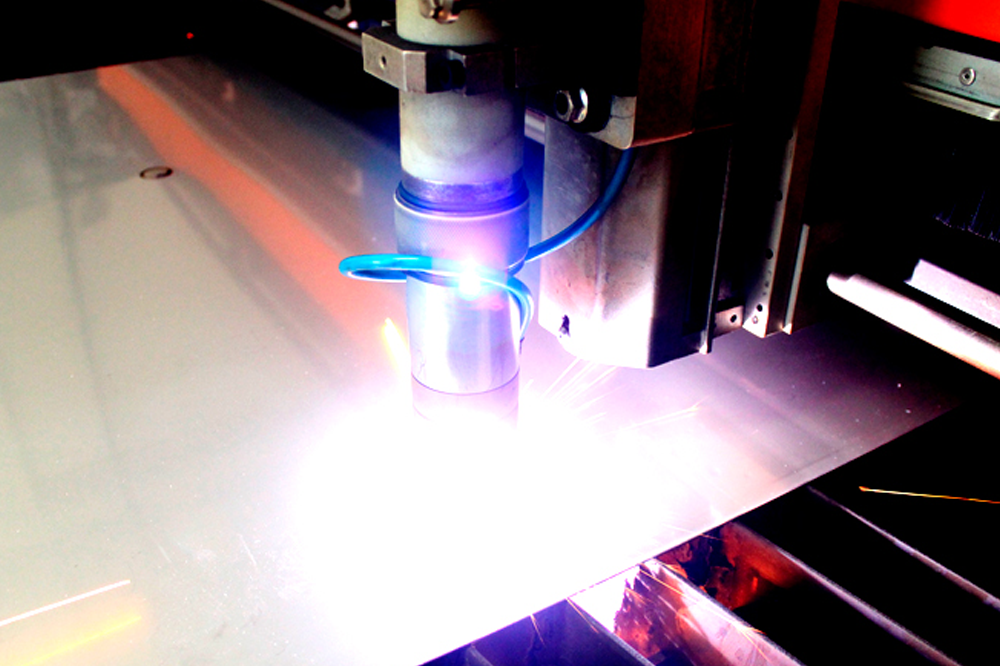

We are ductile and malleable, like the precious and noble metal we work with. We perform welding, bending, shearing, calendering, tube bending and bending, HD plasma and laser cutting, light carpentry and design, electropolishing, pickling directly in our factories. Micro shot peening, passivation, tumbling, satin finishing on the surface and on cylinders, both on products made by us on behalf of customers and on products produced by customers and processed by us for finishing.

The articles of our production are intended for many sectors such as food & beverage, agriculture, oenology, the hospital, health and medical sectors, the nautical sector and swimming pools, sports, objects and industrial, interior and exterior furnishings, dairy, engineering, architecture and construction. The wide range of services and processes that the Condor company provides distinguishes it worldwide, as the product is entirely made internally, starting from the sheet metal and arriving at the finished and certified product.